Academia.edu no longer supports Internet Explorer.

To browse Academia.edu and the wider internet faster and more securely, please take a few seconds to upgrade your browser .

Enter the email address you signed up with and we'll email you a reset link.

- We're Hiring!

- Help Center

Pneumatic Trainer Kit

Electro pneumatics is successfully used in many areas of industrial automation. Production, assembly and packaging systems worldwide are driven by electro pneumatic control systems. The change in requirements together with technical advances has had a considerable impact on the appearance of controls. In the signal control section, the relay has increasingly been replaced by the programmable logic controller in order to meet the growing demand for more flexibility. Modern electro pneumatic controls also implement new concepts in the power section to meet the needs of modern industrial practice. Examples of this are the valve terminal, bus networking and proportional pneumatics. In introducing this topic, this project first looks at the structure and mode of operation of the components used for setting up an electro pneumatic control. The following chapters then look at the approach to project planning and the implementation of electro pneumatic controls using fully worked examples. Finally, we had a positive approach towards our project and by looking towards the trends and developments in electro pneumatics this work was completed which would be a path shown by us towards the development of electro pneumatics trainer kits. Our work was based on controllers and relays but not on P.L.C, but we would rather say that if neglecting the cost of P.L.C, this kit could also be controlled from remote places also and better controlled signals could also be delivered if we had used P.LC. Our circuits are based on 24 V D.C and working pressure was 0.15 MPa to 0.8Mpa.we had found that by considering this very working pressure the valves/cylinders behave in a good manner rather than creating a hammering effect by using more air pressure.

Related Papers

Jeff Pereyras

A basic electro-pneumatic control trainer provides the students’ learning experience and appreciation of the subject and course and for the professors’ demonstrations and evaluation of students’ performance during laboratory time. This study utilized a developmental type of research. The trainer board was a 24 inches by 24 inches by ¾ inch marine plywood. It was cost-effective, space-efficient and portable. It contained circuit breaker, plurality of din rails, plurality of terminal blocks, plurality of relays and relay holders, plurality of normality open and closed push buttons, plurality of utility box, plurality of base plates, plurality of 24VDC (Volt-Direct Current) 3/2 way solenoid valves, plurality of 24VDC indicator lights, tubes duct, plurality of double-acting cylinders, plurality of clamps, and plurality of 24VDC proximity sensors. All the devices were totally exposed for easy installation and familiarization. The plurality of input and output devices terminals were pre-w...

Gerardo Salazar

IMK-14 - Istrazivanje i razvoj

Milan Marjanović

Studying the dynamic behaviour of objects or systems in response to conditions cannot always be easily or safely applied in real life. Computer simulations in engineering are very important as it solves real-world problems safely and efficiently. It provides an important method of analysis which is easily verified, communicated, and understood. Across industries and disciplines, simulation modelling provides valuable solutions by giving clear insights into complex systems. A system presented in this paper is a pneumatic sheet metal bending laboratory setup. An electro-pneumatic motion control of this system is modelled and simulated in FluidSim software. This system is also physically built using main pneumatic and electrical components with PLC. Described laboratory setup in this paper was used in the education of students and significant enchantment in the understanding of how similar systems work was noticed.

International Journal of Science Technology & Engineering

IJSTE - International Journal of Science Technology and Engineering

Programmable logic controllers are used in industry in many areas of automation and technology as well as for control and regulation tasks. A PLC is a device with specialized input and output interfaces. These interfaces (sensors and actuators) to regulate, controls and monitors the manufacturing processes. While designing pneumatic circuit's more than one cylinder using cascade circuits or KV design in basic pneumatics and electrical relays with timer and counter circuits in electro pneumatics is complicated and using limited cylinders only. Thus the complicated circuits using more number of cylinders can easily be implemented by programming using any kind of PLC or Arduino microcontroller .When comparing the cost of Arduino microcontroller ten times less than the PLC unit. Moreover interfacing devices of input sensors are easily adoptable one with low cost and can be interfaced to any kind of output environment like OLED display, Bluetooth, WIFI control and I O T control system.

Proceedings of the Canadian Engineering Education Association

Giorgio Figliolini

This paper deals with the teaching activity on the design and test of pneumatic and electro-pneumatic systems, which is carried out at the University of Cassino in Italy, since the academic year 1994 / 95. In particular, the design and test of a vacuum gripper and an automatic packaging machine, are proposed as examples of components and systems operating in on/off environment. Likewise, a proportional pressure valve and a robotic automatic packaging are presented as examples of components and systems operating in analogue environment for the production automation.

International Journal of Online Engineering (iJOE)

Ivana Milenkovic

Jigarkumar Gohil

Mechatronics is an immerging branch in the present era which deals with mechanical systems, instrumentations and electronic systems. Hydraulic and Pneumatic systems are the vital elements of Mechatronics system. The actuation of hydraulic and pneumatic system can be done using a PLC or a microcontroller. The programming could be done in a ladder language, Functional block diagram or in embedded C. This paper shows the methodology for interfacing the MATLAB simulink with pneumatic system via microcontroller without any burden of programming. To fulfil this purpose, MATHWORKS has designed Arduino I/O packages, to communicate with Arduino controller without any programming language. The system consists of a relay unit, Arduino Microcontroller, Arduino IDE software, MATLAB simulink (Version 2012 or beyond) SMPS, Direction controlled solenoid operated valve, Double acting pneumatic cylinder and a USB cable. In a nut shell this methodology will not only decrease the load of programming bu...

IAES International Journal of Robotics and Automation (IJRA)

ali akbar mohammadi

International Journal of Sustainable Energy Development

Michail Papoutsidakis

Abdulrazak Hussainbaig

The classic methodologies of electro-pneumatic control are essentially based on the Cascade method and a methodology supported by Karnaugh Map. If in the first method, the resolution of pneumatic problem is basically performed by dividing the working sequence in groups, in the second method, the approach is made by the minimization of the control logic equations converting the truth table, to the corresponding logical circuit. In this paper we present an alternative form of a PLC programming, using the Cascade and Karnaugh methods, replacing the classic technique supported by the Grafcet modelling. 1. Introduction-The compressed air as power source is widespread in the industry in handling tasks and assembly, and also in large office buildings like hospitals, banks, supermarkets, to carry small objects, such as medications, notes, etc. On the other hand, from the standpoint of pneumatic systems, while actuation systems, are considered economic, robust and compact solutions. It is for these reasons; its use is widespread in industry, in handling tasks and assembly. In pneumatics, the generally necessities is to automate sequential processes. In this type of case, control of the power parts (cylinder) is not only depending on the state of the information present but also in terms of knowledge of past actions. In practice, ensure a series of sequential movements in an automatic cycle is to find the set of equations which are executed ensure the realization of the desired sequence. The application of these methods makes it unnecessary to analyze the speed or course of stakeholder's cylinders (irrelevant features to the materialization of the command sequence). It means therefore that the control equations of the cylinders that will allow their advance and their indentation (called output variables) are function only of two types of variables (input variables) and positioning each intervening cylinder (signal end-of-course) and if necessary memory variables [1]. In both pneumatic approaches, Cascade and Karnaugh, the electric control circuit of the pneumatic cylinders is obtained by the results of equations of motion and the transcription of the Cascade method or obtained directly from the equations of motion of the pneumatic cylinders derived by Karnaugh map [2], in analogy to the modelling methodology of Grafcet (conversion of the evolution of GRAFCET and actions control equations). The proposed method not only ensures the desired sequential pneumatic cycle implementation, as well as the electrical control in the PLC, the direct implementation of the orders resulting from the application of the two methods (Cascade and Karnaugh), according to the rules associated with each of the methodologies and the conditioning of the states or from memories used.

Loading Preview

Sorry, preview is currently unavailable. You can download the paper by clicking the button above.

RELATED PAPERS

mumtaz khan

Snežana Dragićević

ISA Transactions

International Journal of Advanced Trends in Computer Science and Engineering (IJATCSE)

WARSE The World Academy of Research in Science and Engineering , Jeff Pereyras

Tolga Hasdemir

IOP Conference Series: Materials Science and Engineering

ibrahim burhan

Agron Pajaziti

International conference Fluid Power 2019: Conference Proceedings

Zeljko Situm

Journal of Industrial Engineering

Luiz A Rasia

International Journal of Computer Applications

D. Papachristos

Mihai Diaconu

Xavier Brun

Transstellar Journals

TJPRC Publication

Editor IJRET

Procedia Technology

Jesus Guzman

RELATED TOPICS

- We're Hiring!

- Help Center

- Find new research papers in:

- Health Sciences

- Earth Sciences

- Cognitive Science

- Mathematics

- Computer Science

- Academia ©2024

(512) 203-0590

- Virtual Demo

- No products in the list

Shop by Solution

Check out our variety of solutions and find a suitable one for your institution.

Not sure where to start? Contact Sales

- Manufacturing

- Fluid Power

- Mechatronics

- Process Control

- Industry 4.0

- Additive Manufacturing

- Semiconductor Industry Training Initiative

- EVs / Hybrids

- Diesel & Heavy Truck

- Ag Mechanics

- Renewable Energy

- Skilled Trades

- Construction

- Classroom Furniture

- Industrial Furniture

- Certifications

- Flight Pilot Simulator Training

- Aviation Maintenance Training

- View all products

Browse programs & paired products for your institution.

Not sure where to start? Contact Us

- Diesel/Heavy Truck Technology

- Automotive Technology

- Supply Chain & Logistics Technology

- Heating, A/C & Refrigeration Technology

- Construction Management

- Renewable Energy Specialization

- Electronics Technology

- Electrical Engineering Technology

- Industrial Maintenance

- Manufacturing, Automation & Robotics

- Advanced Manufacturing

- Marketplace

SMC Pneumatics Training System

Pneutrainer-400

Pneutrainer-with-Simualtion

pneutrainer400

SMC , the worldwide leading manufacturer of Pneumatic Components and Technologies, has developed the most state-of-the-art and robust training system for teaching Pneumatics and Electro-Pneumatics Fundamentals to schools, training centers, and colleges. All components are industrial, used by companies around the world, so you can rest assured that your pneumatics learning directly translates to on-the-job relevance.

The Pneutrainer-400 comes with modular design that allows several customizable options to suite your training needs. Choose you form factor (mobile cart or tabletop), single or double-sided, and choose your training package!

SMC Pneumatics training systems are complete with interactive lesson plans, curriculum, user activities, eLearning and simulation software for the world’s most complete and comprehensive Pneumatics training platforms.

Pricing upon request

Form Factor

Pneumatic training sets, single-sided or double-sided.

- Subjects & Skills

- Specifications

- Product Video

- Product Docs

Description

Who is smc.

SMC , the world’s largest manufacturer of pneumatic components and technologies , has developed the most state-of-the-art and robust training system for teaching Pneumatics and Electro-Pneumatics fundamentals to schools, training centers, and colleges.

All components are industrial, used by companies around the world, so you can rest assured that your pneumatics learning directly translates to on-the-job relevance.

Modular Training

Modular Options allow for standard training on all-industrial components.

– Fundamentals of Pneumatics

– Advanced Pneumatics

– Fundamentals of Electro-Pneumatics

– Advanced Electro-Pneumatics

– Fundamentals of Pneumatics and Electro-Pneumatics

– Proportional Pneumatics

– Vacuum Technology

Industrial training that meets your needs!

Training Activities

The modular design of the SMC Pneutrainer-400 allows for hands-on training in basic pneumatics concepts and safety skills while also being able to teach more advanced topics all on the same platform.

- Air flow control and measurements

- How to operate, install, design, and troubleshoot pneumatic circuits

- Real-world technology training in Flow Control, Air Filters, Rotameters, Pressure Gauges, Air Motors, and Directional Control Valves

- Real-world skills development on industry-leading technologies

Relevant Subjects

Designed for:.

- High School

- Technical College

Additional information

| Manufacturer |

|

|---|---|

| Features | Industry-leading Pneumatic, Modular Options, Industrial Components, Industry-Validated Certification, Quick-Connect, Safe, Skills-Relevant, Blended Learning, Simulations, Double-Sided |

Product Documents

- Pneutrainer-400 Datasheet

Learn more about SMC and Toolkit’s incredible software options to complement your pneumatics training.

SMC autoSIM-200

SMC eLearning-200

A Global Manufacturing Leader

The World's Largest Manufacturer of Automation and Pneumatic Control Technologies for industrial companies brings its industrial know-how and innovation to technical training programs.

Every SMC training system features all industrial components commonly found in manufacturing settings across the globe, including SMC's industry-leading Directional Control equipment, Actuators, modular Filters, Regulators, and Lubricators, Air Preparation equipment, Fittings and Tubings, Flow Control equipment, Solenoid Valves, Digital Pressure Switches, and Electric equipment.

The equipment and technologies students train on in the classroom, are the very same equipment and technologies they will see and use in their future workplace(s).

Our SMC Training Systems are designed around SKILLS.

The skills needed by students, technicians, and engineers to be successful in industry today ;

The skills for a changing workforce and rapidly evolving industrial future ; and,

The skills to create the future leaders of industry.

SMC Training Systems are focused on critical thinking skills and technical mastery of technologies and concepts - our goal is NOT to train students on how to follow instructions ; but rather how to empower oneself with the tools (technical aptitude) to be successful in the career of their choosing.

SMC's Technology Trainers are built upon the principle that a solid foundation is paramount to creating students with technical expertise in their field, regardless of how advanced it may be.

SMC Technology Trainers are best-in-class modular training platforms that are complete with step-by-step curriculum and user manuals, simulation tools, and engaging digital solutions to further expand student understanding.

- Basic Electrical Trainers - AC, DC, and Solid State

- Pneumatics and Electro-Pneumatics

- Hydraulics and Electro-Hydraulics

- Mechanical Drives

- Programmable Logic Controllers and Human Machine Interfaces

- Industrial Robotics

- Industrial (Motor) Controls

- Sensors and Smart Sensors

- Vacuum Technology

The bread-and-butter of SMC: Automation and Integrated Systems.

SMC's integrated mechatronics and automated assembly training systems provide students with hands-on, real-world manufacturing systems for practical skills development. Mechatronics combines topics in mechanics, electronics, computing and robotics into one diverse area, and SMC's mechatronic training systems give students an in-depth look at programming, wiring, installation, troubleshooting, and more!

From tabletop mechatronics systems like the Automate-200 Urban Recycling Training System to complete industrial assembly lines like the Flexible Manufacturing System, SMC has a training solution for your school.

SMC, a pioneer of Industry 4.0 technology for commercial customers , brings its real-world technology and expertise to education with world-class i4o training platforms.

Integrated physical, digital, and cyber-physical solutions make up SMC's comprehensive Industry 4.0 portfolio for Advanced Manufacturing training.

Complete smart factories with Industrial Robots, Mobile Robots, Smart Sensors with IO-Link, IIoT, Identification Systems like RFID, NFC, Bar Codes, MES Software, Data Collection and Analysis, Artificial Intelligence, Machine Learning, Cyber Security, Digital Twins, and more.

SMC's all-encompassing i4o solutions range from tabletop and compact introductory Industry 4.0 Training Systems to complete smart factories.

Don't see a training system that fits your training needs exactly?

A global group of world-class engineers make up SMC's Custom Solutions Team - and we welcome any challenge to design and build the training system for your specific needs.

Need a reference? Ask our partners at Intel, Rockwell Automation / Allen-Bradley, Honda, Toyota, Kia, and More.

Award Winning Simulation Software - autoSIM-200

SMC's autoSIM-200 software is the best turn-key software package for designing, viewing, simulating, monitoring and controlling Pneumatic, Hydraulic, Electrical, and Electronic Circuits.

autoSIM-200 is a one-for-one complement of SMC's hands-on training systems , allowing students to train by wiring circuits and programming systems virtually before applying them to the physical system.

The 2D and 3D packages allow for students to complete actual lab activities and curriculum exercises in the virtual simulator before completing them on the hands-on training equipment.

Comprehensive eLearning

Our engaging and interactive , web-based eLearning represents a major achievement of providing students "hands-on" training access in a virtual environment.

All major areas of Automation are taught in easy-to-digest bite-sized nuggets broken up into different topics such as Alternating Currents, Direct Currents, Solid State Devices, Pneumatics, Hydraulics, Robotics, PLCs, Sensors, Process Control and More!

Looking for Soft Skills eLearning, Trades-focused eLearning, Measurement, Tools, etc? Just Ask!

Some of our SMC Partners...

THE SMC DIFFERENCE

Complete curriculum.

All SMC International Training products are complete with all learning materials for successful implementation in the classroom and/or lab. All training systems include user manuals, activity guides, and access to wiring, electrical, and mechanical schematics, in addition to complete PLC programs and diagrams.

SMC curriculum is designed to meet you at your level , with as much hand-holding as necessary, and take you to our standard: industry .

Industry Driven

All SMC Training Systems are made up entirely of industrial components and systems .

As the global leader in such technologies, it is likely that the components your students use on our training systems will in fact be the same technologies and components they see when they enter the workforce.

Our reference is industry .

From Industry . For Industry .

GET CERTIFIED

SMC Training Systems and associated Curriculum are designed to be aligned with most industry-recognized credentials, including SMC's Industry 4.0 Specialist Certification Pathway , and all associated micro-credentials.

Our Skills-Driven approach to technical training means each course can be cross-walked and aligned with industry-validated micro-credentials.

Related products

Pumps Training System

SMC Hydraulics Training System

SMC Transparent Hydraulics Training System

Cutaway Starting System Trainer

Pneumatic Trainer Kit & Its Components by Niyo Engineers India

Nov 11, 2022

20 likes | 54 Views

Niyo Indiau2019s Pneumatic Trainer Kit helps trainees understand basic and advanced concepts of pneumatics and electro- pneumatics. The trainer kit consists of a work surface, components, electrical and electronic control panel, silent air compressor & more. For more details: https://www.niyoindia.com/solutions/technical-and-vocational-training-equipment-institute/pneumatic-trainer-kit/ or Contact on: 91 2025465004

Share Presentation

Presentation Transcript

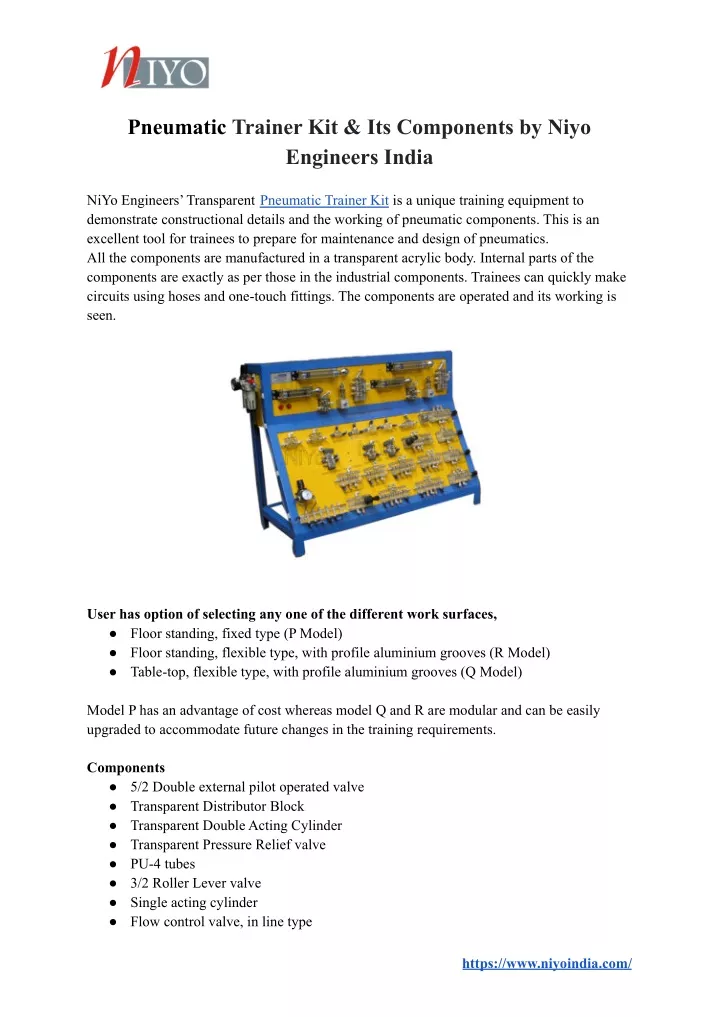

Pneumatic Trainer Kit & Its Components by Niyo Engineers India NiYo Engineers’ Transparent Pneumatic Trainer Kit is a unique training equipment to demonstrate constructional details and the working of pneumatic components. This is an excellent tool for trainees to prepare for maintenance and design of pneumatics. All the components are manufactured in a transparent acrylic body. Internal parts of the components are exactly as per those in the industrial components. Trainees can quickly make circuits using hoses and one-touch fittings. The components are operated and its working is seen. User has option of selecting any one of the different work surfaces, ● Floor standing, fixed type (P Model) ● Floor standing, flexible type, with profile aluminium grooves (R Model) ● Table-top, flexible type, with profile aluminium grooves (Q Model) Model P has an advantage of cost whereas model Q and R are modular and can be easily upgraded to accommodate future changes in the training requirements. Components ● 5/2 Double external pilot operated valve ● Transparent Distributor Block ● Transparent Double Acting Cylinder ● Transparent Pressure Relief valve ● PU-4 tubes ● 3/2 Roller Lever valve ● Single acting cylinder ● Flow control valve, in line type https://www.niyoindia.com/

● 5/2 External Pilot operated valve with spring return ● OR Valve ● 3/2 push-pull valve ● Transparent Pressure gauge ● FRL with gauge ● Transparent Non return valve ● 5/2 Hand lever with spring return ● AND Valve [Read More] For More Details Email address [email protected] Contact Number +91 20 25465004/25467296/25468051 Our address 26, Pragati Industrial Complex, Plot No. 5, Kothrud, Pune 411038 https://www.niyoindia.com/

- More by User

What is a Pneumatic Trainer Kit, and Components of Pneumatic Trainer Kit?

Table of Contents

What is a Pneumatic Trainer Kit ?

Pneumatics is a branch of science related to air that has been successfully used in various areas of industrial automation. Its trainer facilitates the industrial professionals and students to explore various fundamentals of pneumatics. It states how a single device can be used to command, direct, regulate, and manage the behavior or other system.

The working medium in pneumatics is compressed air and presently this working medium has gained popularity in industries such as petroleum, food & beverage, machinery, robotics, gases, etc. The reason for its popularity is that it is non-hazardous to the environment and fire-free.

It is abundantly available in nature and is simple, easy, and safe to operate. Pneumatic Trainer Kits are known to assist users in understanding the pneumatic components’ as well as different actuators’ principal performance. It also has another feature which is the automatic and manual based control which it possesses.

Pneumatic trainer kits are the kits that have been well tested according to the industry parameters by a team of experts. This team gives assurance regarding the quality of the final product. These kits are known for their precision and accuracy.

Pneumatic systems are used to control automatic production lines, mechanical clamps, and train doors. Pneumatic trainers provide various types of valves including both mechanical and electronic. This helps in understanding the user about automatic and manual processes. There are wide ranges of experiments which are provided on the trainer that can be performed.

Pneumatic training kits help in teaching the fluid power to industry professionals and the students. The pneumatic training system consists of flow controls, pressure gauges, filters, cylinders, directional control valves, and an air motor. Its components are pre-mounted in a user-friendly manner on stainless steel circuit panels with shadow labels.

All this helps in the easy identification and tracking of components by providing a well-designed learning experience that serves the students and instructors for years.

What Is Pneumatic Process ?

A pneumatic system provides an easy and cost-effective means to clamp, rotate, screw, and grind in machine automation. This system is a collection of numerous interconnected components that utilizes compressed air to perform work for automated equipment.

A pneumatic system consists of a method of generating compressed air to power the system. It is mostly a plant air compressor and often includes pressure tanks for distribution piping to equipment and machines and reserving air.

The work here is produced in form of a rotary or linear motion. The pressurized gas or compressed air is filtered and dried to protect the actuators, tools, cylinders, and bladders performing work. A lubrication device is required by some applications which add oil mist to the closed pressurized system.

The pneumatics process consists of the application of fluid power in which the use of gaseous media is done under pressure to generate, control, and transmit power. It is typically compressed using a gas such as air at a pressure of 60 to 120 pounds PSI.

Pneumatics is generally used because of its simplicity; machines can be combined easily and quickly using pneumatic components such as cylinders and valves. Pneumatic systems are reliable and provide service for a very long span with little requirement for maintenance.

Components of Pneumatic Trainer Kit

The components of the Pneumatic Trainer Kit include a compressor, FRL, or Filter Regulator Lubricator and consume compressed air. Let’s read about these components in detail.

A compressor is used to compress air as per the required pressures. It comprises the power to convert the mechanical energy from engines and motors into potential energy in compressed air.

A single central compressor is capable of supplying a wide range of pneumatic components by utilizing compressed air. This air is transported via pipes from the cylinder to the pneumatic components.

Compressors are generally of two types – rotary and reciprocator. Pneumatics or any other kind of energy transmission is used on a machine to perform work. To accomplish work, the application of kinetic energy to a resisting object is required resulting in the object moving through a distance.

The energy gets stored in a potential state under the form of compressed air in the pneumatic system. The working energy which consists of kinetic energy and pressure results in a pneumatic system when compressed air is allowed to expand.

Filter Regulator Lubricator (FRL)

This component of the pneumatic system is a combination of three individual components filter, regulator, and lubricator which are crucial for a pneumatic circuit. Filter holds the power to remove impurities from compressed air before it is fed to the pneumatic components.

The pressure regulator regulates the operation of pneumatic components and stabilizes the pressure while the lubricator provides lubrication for pneumatic components.

You can read also: What Is an Electronic Component? Details About Electronic Components!

Consumption of Compressed Air

Execution components like cylinders, assistant valves, and directional control valves are some of the examples of components that consume compressed air.

Execution Components

The execution components of pneumatics provide rectilinear of rotary movement. Examples of pneumatic components include pneumatic motors, cylinder pistons, etc. Cylinder pistons produce rectilinear motion while pneumatic motors are known for providing continuous rotations. Cylinders are of different kinds such as single and double-acting cylinders.

Single Acting Cylinder

A single-acting cylinder has a single entrance through which the compressed air flows. Therefore, it is only capable of producing thrust in one direction. With the help of an internal string, the piston rod is propelled in the opposite direction or by an external force which is provided by the mechanical movement or weight of a load.

As the piston rod has to overcome the force from the spring, therefore the thrust from it is greatly lowered. The diameter of the cylinder is also increased so as to provide the driving force for machines. The length of the cylinder should also be increased in order to match the length of the spring, thus limiting the length of the path. Single-acting cylinders are generally used in stamping, moving materials, and printing.

Double Acting Cylinder

After a single-acting cylinder, let’s read about a double-acting cylinder. In a double-acting cylinder, propelling force and a retracting force is produced by applying air pressure to the relative surface of the piston. The thrust produced during retraction is relatively weak as the effective area of the piston is small.

Generally, the impeccable tubes of double-acting cylinders are made up of steel. The working surfaces are polished and coated with chromium in order to reduce friction. These cylinders usually consist of two fluid chambers so that the pressure can be utilized to extend and retract the rod.

Here, the sealing devices work in both directions. A double-acting cylinder is the most common type of cylinder which can be used in almost all types of applications. It has been observed that the effective working area of the rod side of the piston is less than that of the other side. Therefore, the double-acting cylinders are known to retract faster than they extend. Not only this, they exert less force on the retraction stroke.

Directional Control Valve

Directional control valves are the valves that ensure the flow of air between various ports by switching, opening, and closing their internal connections. The classification of these valves can be determined by the number of ports, the normal position of the valve, the number of switching positions, and its method of operation.

The most common types of directional control valves include 2/2, 3/2, 5/2, etc. In these, the first number represents the number of ports while the second number represents the number of positions. A directional control valve that has five positions and two ports can be represented by its unique pneumatic symbol or a drawing.

Control Valve

The control valve consists of a push-button, a flow control valve, and a shuttle valve. A push-button is a micro switch style mechanical valve designed as a 3/2 – Push-button.

A flow control valve is used to control the flow of fluid which can be regulated from zero to a maximum possible via the particular aperture size. A shuttle valve is also known as a single or double control non-return valve. It has two air inlets and one outlet.

Manifolds are basically fluid distribution devices that range from simple supply chamber to multi-chambered flow control units. The simple supply chambers consist of several outlets while the multi-chambered flow control units include integral valves and interfaces to electronic networks.

Pressure Gauge

The pressure gauge is an instrument that is used for measuring and indicating the “Pressure” of a specific instrument.

Read also: Essential Physics Lab Equipment.

What Is the Purpose of Pneumatics ?

Pneumatic systems are widely and extensively used in a variety of industries to significantly help perform different mechanical processes. They are highly effective and use compressed air to perform tasks. These systems play a crucial role in all types of assembly and fabrication applications. They can be easily installed for maintaining facilities to move items and to move items on assembly lines.

[mks_button size=”medium” title=”Buy Pneumatics Trainer Kits” style=”squared” url=”https://www.tescaglobal.com/product-list/pneumatic-trainers.html” target=”_blank” bg_color=”#ff3838″ txt_color=”#FFFFFF” icon=”” icon_type=”” nofollow=”0″]

The purpose of pneumatics is to generate repetitive action that is why it is also used with heavy machinery like drills. Air brakes used in vehicles like trucks, trains, cars, and buses are the most common examples of usage of pneumatic technology. These vehicles stop when a change in the pressure level takes place inside a closed air circuit.

Dental drills are yet another example of the application of pneumatic technology. Since it uses air, it is the safest way to perform the dental drills. Although it is known for creating unpleasant noise, it is the safest way to accomplish it. There are many other tools found in medicine that make use of compressed air.

Jackhammers used at a construction site are generally connected to a compressor with the help of an air hose. Pneumatic technology is used here to perform hard tasks like breaking up concrete. Cable jetting experts apply this technology to running lengths of wire; paint sprayers and other tools also use compressed air to perform various tasks.

Is Hydraulic Better Than Pneumatic?

Hydraulic systems can easily move heavier loads and are capable of providing greater force compared to pneumatics. However, pneumatics technology is cleaner, and leaks (oil or hydraulic fluid) aren’t a big concern in it.

Hydraulics is generally not used in food manufacturing processes, unlike pneumatics because of the leakage risk that it holds. These leakages may occur from seals, faulty valves, or burst hoses.

The working fluid or gas in the pneumatic system absorbs the excessive force which reduces the damage frequency. Although the compressible gases which are used in

You can read also: What Is Hydraulic System and How Does it Work?

the application of pneumatics system can be easily stored, its components do require regular maintenance.

Pneumatics are known for the rapid movement of cylinders and are easily available in small sizes. It offers high operating speed of its components whereas hydraulic system requires more energy to move because it uses oil.

In pneumatics, the valves and cylinders dump the compressed air in the atmosphere. This happens when they change their direction whereas, in hydraulics, the oil must be routed back to the reservoir.

Both pneumatics and hydraulics have pros and cons with unique scope for utilization. In fields that require carrying and moving heavy loads, hydraulics is a more appropriate medium while in food factories, following pneumatics is a safer option.

What Are the Advantages and Disadvantages of Pneumatic Systems ?

Every system has its advantages and disadvantages, let’s read what pneumatic systems have in store.

Advantages of Pneumatic Systems

The design and control of these systems are created in a simple manner which makes it easy to operate. They are designed using high standard cylinders, and other components.

Since the major ingredient in the pneumatic system is air, there is no need for any additional purchase as it is already present in abundance in the atmosphere. In case of a leakage, this system does not contaminate the environment.

Many parts of the pneumatic systems are made up of affordable materials like aluminum, plastics, and zinc. These materials are easily available and are inexpensive which makes it a cost-effective system. These systems require limited cleaning as nothing gets inside them except the air.

The pneumatic systems are reliable as they usually have long operating lives and need very little maintenance. Since the gas is compressible, the equipment is not much prone to shock damage.

As compressed gas can be easily stored, the machines keep running for a while even after the electric power is lost. There is a very minor chance of fire in the case of a pneumatic system; new machines are generally overloaded safely to a certain extent.

Disadvantages of Pneumatic Systems

A disadvantage of the pneumatic system is that a little leak can make it unusable. It is a two-stage system that requires a constant supply of air at a certain pressure which can be identified by a static air pressure gauge.

Pneumatic systems are sensitive to any intrusion by water, vibrations, changing temperatures, and lack precision controls. It is observed that the speed and control of these systems are difficult because of the compressed air. The other disadvantage of the pneumatic systems is that they are too loud and noisy.

Why Tesca Technology is Best Pneumatic Trainer Kit Manufacturer, Suppliers, and Exporters?

Tesca Technology is not only a leading but the manufacturer, supplier, and exporter of the Pneumatic Trainer Kit. There are several factors responsible for making us the best in our field. Some of these are as follows.

Every product that we deliver is checked thoroughly, quality control is done at multiple stages. It’s only when we are sure of our product’s quality that we carry it forward. We follow stringent rules when it comes to the quality of our product with no scope for carelessness.

We are known for providing high-quality services to our customers and are always ready to provide service support whenever need be. We provide hassle-free shipment ordering which has made us our global clients’ favorite. Here is a list of some of the Pneumatic Trainer Kits that we offer.

- Pneumatic Trainer without Compressor

- Electro-Pneumatic Trainer without Compressor

- Electro-Pneumatic Trainer

- Basic Pneumatic Trainer Kit (Transparent) With Inclined Profile W/o Compressor

- Basic Pneumatic Trainer Kit With Inclined Profile W/o Compressor

- Advanced Pneumatic Trainer Kit With Inclined Profile W/o Compressor

- Basic Electro Pneumatic Trainer Kit With Inclined Profile W/o Compressor

- Advanced Electro Pneumatic Trainer Kit With Inclined Profile W/o Compressor

- Basic Electro Pneumatic Trainer Kit PLC With Inclined Profile W/o Compressor

- Advanced Electro Pneumatic Trainer Kit PLC With Inclined Profile W/o Compressor

We have a team of professionals consisting of engineers, technicians, warehousing personnel, allied workers, and quality controllers. We believe in providing the best to our customers each time and therefore work tirelessly to reap so. We have a variety of products among which you may choose the one which suits your requirements.

If you are planning to buy a Pneumatic Trainer Kit , be assured of its quality as this is what we are known for around the globe. Happy Purchasing!

Related posts:

- PLC Trainer Kit: All You Need to Know with Manufacturers

- A Complete Guide on LED TV Trainer Kit With Explanation

- An Extensive Guide on Digital Trainer kit Educational Tool

- DSB SSB Amplitude Modulation and Demodulation Trainer Kits

Contributing towards United Nation’s Sustainable Development Goals of Quality Education, Industry, Innovation & Infrastructure.

Add comment

Cancel reply.

Save my name, email, and website in this browser for the next time I comment.

This site uses Akismet to reduce spam. Learn how your comment data is processed .

You may also like

- Unveiling the Future of Educational Systems: Embracing the EdTech Revolution

Table of Contents The Future of Educational Systems: A Glimpse into EdTech1. Current Challenges in Education2. The Rise of EdTech3. Empowering Teachers with EdTech4. Transforming the Learning Experience5. The Role of...

- Transforming Education: The Vital Role of AI in Modern Educational Systems

Table of Contents Embracing AI in Education1. Understanding AI in Education1.1 The Emergence of AI in Educational Settings1.2 Benefits of AI Adoption in Education2. Personalized Learning through AI2.1 Tailoring...

- Safe Handling and Maintenance of Lab Equipment: A Guide

Table of Contents 13 Tips to Safely Use and Maintain Lab EquipmentTypes of Lab Equipment1. General Safety Guidelines in the Laboratory2. Safe Usage of Common Lab Equipment3. Maintaining Laboratory Glassware4...

- The Significance of Lab Equipment in STEM Education

Table of Contents What is STEM Education?Importance of Hands-on LearningThe Role of Lab Equipment in STEM Education1. Understanding Theoretical Concepts through Experiments2. Developing Analytical and Critical Thinking3...

PRODUCTS CATEGORIES

- EDUCATIONAL TRAINER / SOFTWARE

- TEST & MEASUREMENT INSTRUMENTS

- E-LEARNING LMS / CMS

- SCIENCE LAB

- MECHANICAL & CIVIL LAB

- CIVIL ENGINEERING

- HAND / POWER TOOLS

- ELECTRONIC COMPONENTS

- AGRI. PRODUCTS

- LABORATORY PLASTICWARE

- SCHOOL PRODUCTS

- SOLAR PRODUCTS

- WEB & SOFTWARE APPLICATIONS

- CABLES & WIRES

- SWITCH GEAR CONTROL PANELS

- IT – COMPUTERS – NETWORKING

- SOLDERING & DESOLDERING STATION

- VARIACS/DIMMERSTAT

- OIL INSULATION TESTERS

- FLUKE PRODUCTS

- LAB FURNITURE

- INTERACTIVE WHITEBOARDS

Recent Posts

- Tesca Global: Best Lab Furniture Manufacturer In India

[INSERT_ELEMENTOR id="576"]

Tesca specializes in doing turnkey projects that are fully operable when it is handed over to the project authority. Starting from inception to application training, Tesca provides the services as ONE source solution. Working side by side with government authorities and people across the World, we help countries to perform better. We support countries to grow their economies, strengthen their education and health systems and improve financial management. We do this by providing consultancy & training in environmental safety, education, and health strengthening.

ALSO DEALS IN

- Variacs/Dimmerstat

- Laboratory Plasticware

- Whatman Filters

- Science Lab

- Educational Trainers

- Test & Measurement Instruments

- Soldering & Desoldering Station

- Hand / Power Tools

- Authorized Dealers

- CERTIFICATES

- PRIVACY POLICY

- TESTIMONIALS

Copyright © 2024. Created by Meks . Powered by WordPress

- Web Stories

The Pneumatics Trainer

Download Sample Curriculum

Build a Pneumatics Test Module

Pneumatic Principles

- Pneumatic Safety

- The Operation of Pneumatic Components

- Building a Pneumatic Circuit

Science and Engineering Principles

- Force and Torque

- Work and Power

- Levers, Wheels, and Axles

- Piston Force and Pressure

- Pressure and Boyle’s Law

- Air Storage Capacity and Flow

Design Principles

- Subassemblies and Components

- Linkages and Power Transfer

- Rigidity and Structures

- Threaded Fasteners

Mathematics

- How to Create and Use Basic Mathematical Models to Evaluate and predict Component Performance

- Using Spread Sheets to Assess Performance

- Algebraic and Geometric Manipulations

History of Science and Technology

- Physicists, Chemists, and Philosophers that contributed to the science of Pneumatics

The Pneumatics Trainer Teaches S.T.E.M.

Build and use the pneumatic test module to explore engineering principles.

Students build their own pneumatic test module using industry grade components. The kit includes linear actuator, regulator, solenoid, air reservoir, switches, and structural components. The program includes S.T.E.M. based pneumatic lessons.

This project can be used to introduce or reinforce concepts and skills related to fluid power, mechanical linkages, volume, area, force and pressure, Boyle's Law, Charles' Law, The Ideal Gas Law, and basic algebraic manipulations. Building and using the GEARS-IDS Pneumatic Test Module is an excellent integrated math, science, and engineering activity. The completed module can be easily converted to an air-powered catapult that can be used as an engineering challenge.

The test module can be built in under one hour by a team of two to three people. Students who build the Pneumatics Test Module learn the operation of pneumatics components and the many engineering principles that govern its operation.

GEARS Supplies Complete Documentation

Full Pneumatics Trainer Project Description

Identify and Assemble the Pneumatic Components

| | | | | |||||||||||||||||||||||||||||||||||||||||||||||

|

IMAGES

COMMENTS

The trainer kit consists of a work surface, components, electrical and electronic control panel, silent air compressor, accessories and storage area. It demonstrates the construction and working of basic components and helps the trainees in the designing and building of pneumatic circuits.

The Pneumatic Trainer Kits are well tested on the stringent industry parameters by the team of experts which assures the quality of the final product. Pneumatic systems are used in controlling train doors, automatic production lines, mechanical clamps, etc Fig. 1. Pneumatic Trainer provides different types of valves such as electronic and ...

This document provides details on the fabrication of a pneumatic trainer kit for educational purposes. It includes: 1) The objective is to understand pneumatic principles and components through constructing simple circuits and industrial applications. 2) Basic components include cylinders, valves, manifolds, switches and more. Circuits will demonstrate logic functions and industrial devices. 3 ...

SMC's autoSIM-200 software is the best turn-key software package for designing, viewing, simulating, monitoring and controlling Pneumatic, Hydraulic, Electrical, and Electronic Circuits. autoSIM-200 is a one-for-one complement of SMC's hands-on training systems, allowing students to train by wiring circuits and programming systems virtually ...

Niyo Indiau2019s Pneumatic Trainer Kit helps trainees understand basic and advanced concepts of pneumatics and electro- pneumatics. The trainer kit consists of a work surface, components, electrical and electronic control panel, silent air compressor & more. ... During download, if you can't get a presentation, the file might be deleted by the ...

Parker's technical training for Hydraulic, Pneumatic, and Electromechanical technology is the best in the World. Systems from a Global Leader. 2 ... SEN40600 1 Diagnostic Kit SEN40601 1 Flow Meter, 1 to 4 GPM SEN40602 2 Diagnostic Tees Bulletin 0240 - B1 1 Student Textbook Bulletin 0240-B8.PSK 1 Lab Manual SEN40601 SEN40602

The pneumatic training system consists of flow controls, pressure gauges, filters, cylinders, directional control valves, and an air motor. Its components are pre-mounted in a user-friendly manner on stainless steel circuit panels with shadow labels.

PNEUMATIC TRAINER. : GOTT-PT-T52www.gott.com.myDESCRIPTION :The Pneumatic Tr. iner will be supply with working table unit. In addition, it may be equipped with an integral power supply and compressor for use in. locations that are not rigged for plant air. This affordable, yet in-depth, training system can improve skills and increase knowledge ...

The Pneumatics Trainer Teaches S.T.E.M. Build and use the Pneumatic Test Module to Explore Engineering Principles. Students build their own pneumatic test module using industry grade components. The kit includes linear actuator, regulator, solenoid, air reservoir, switches, and structural components.

This research paper discusses a pneumatic trainer kit designed by researchers at D.Y. Patil College of Engineering in India. The paper includes: 1) An introduction describing how pneumatics is used in industry and how the trainer kit helps students learn about pneumatic components. 2) A description of the main components included in the pneumatic trainer kit, such as an air compressor, FRL ...

Pneumatic Trainer Kit Dive into the world of pneumatics with our comprehensive Trainer Kit. Perfect for students, technicians, and enthusiasts alike, this ki...

One pneumatic flow control valve with check bypass. Two potentiometers for control of the proportional valves. The electric terminals are easily connected with plain wires or alligator clip leads - both types of which are supplied with the trainer. One squeeze bulb which is used to feed a low pressure air signal to the air pressure amplifiers.

Electropneumatic training kit (Model: Advance) can also be used for basic pneumatic training kit. At a time, 4 students (2 on each side) can work on an Electropneumatic training kit (Model: Advance). Following accessories are provided with Electropneumatic Training Kit for ease of operation: Three way Two position Hand slide valve.

Hydraulic and Pneumatic Training System. Item Number: 850-CD1. Amatrol's Basic Fluid Power Learning System - Double-Sided A-Frame Bench with Two Hydraulic Manifolds (850-CD1) is built to provide for both hydraulic and pneumatic systems training. Equipped with one set of basic hydraulics training (85-BH) panels and basic pneumatics training ...

Basic Pneumatic Training Kit: Horizontal flat face (front) : 950mm x 400mm. Horizontal flat face (back) : 950mm x 400mm. Vertical work area on front face : 950mm x 720mm. Vertical work area on back face : 950mm x 720mm. Following types of valves are provided with Basic Pneumatic Training Kit: Hand Operated / Lever Operated Direction Control Valves.

Pneumatic Trainer Kit (1) - Free download as PDF File (.pdf), Text File (.txt) or read online for free. Scribd is the world's largest social reading and publishing site.

1. Pneumatic Trainer Kit 1.1 Single acting cylinder Symbol Ordering No MP0014 Technical specifications Cylinder bore size 25 dia Stroke 50 mm Type Miniature cylinder (magnetic) Pressure range 0.5 - 10 bar Tubing Connection Inlet / Outlet - ø4 Mounting Turn to Lock / Unlock 1.2 Miniature double acting cylinder Symbol Ordering No MP0018

1.00 - 1.50 No Agreement at all. As evaluated by the students during their laboratory acti vities, the basic electro-pneumatic control trainer is easy to us e and. operate, the learning ...

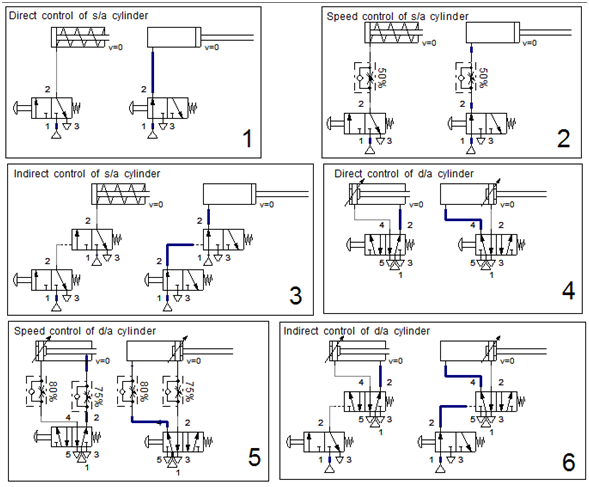

Study of pneumatic actuator & reciprocating cylinder trainer kit with different logical Circuits such as OR, AND etc. operations. Study of pneumatic cylinders, single acting, double acting. Study of construction & operation of pneumatic equipments such as 5/2-way Solenoid valve, 3/2-way valve, limits switches, pneumatic motor etc.

Pneumatic Training Kit - Basic is equipped with most of the commonly used conventional pneumatic valves as well as pneumatic circuit design and simulation software. The valves are mounted on a anodized aluminum profile work bench (double sided) with minimum dimensions of 900mm x 720mm. Electropneumatic Training Kit - Advance is an advanced ...

Please contact: Fluidsys Training Centre Pvt Ltd, Bangalore +91 07338385505 email: [email protected] Website: https://fluidsys.org View all posts by fluidsys. December 17, 2018. pneumatics. AND logic control of a pneumatic cylinder, direct control of a double acting cylinder, direct control of a single acting cylinder, fully automatic control of ...